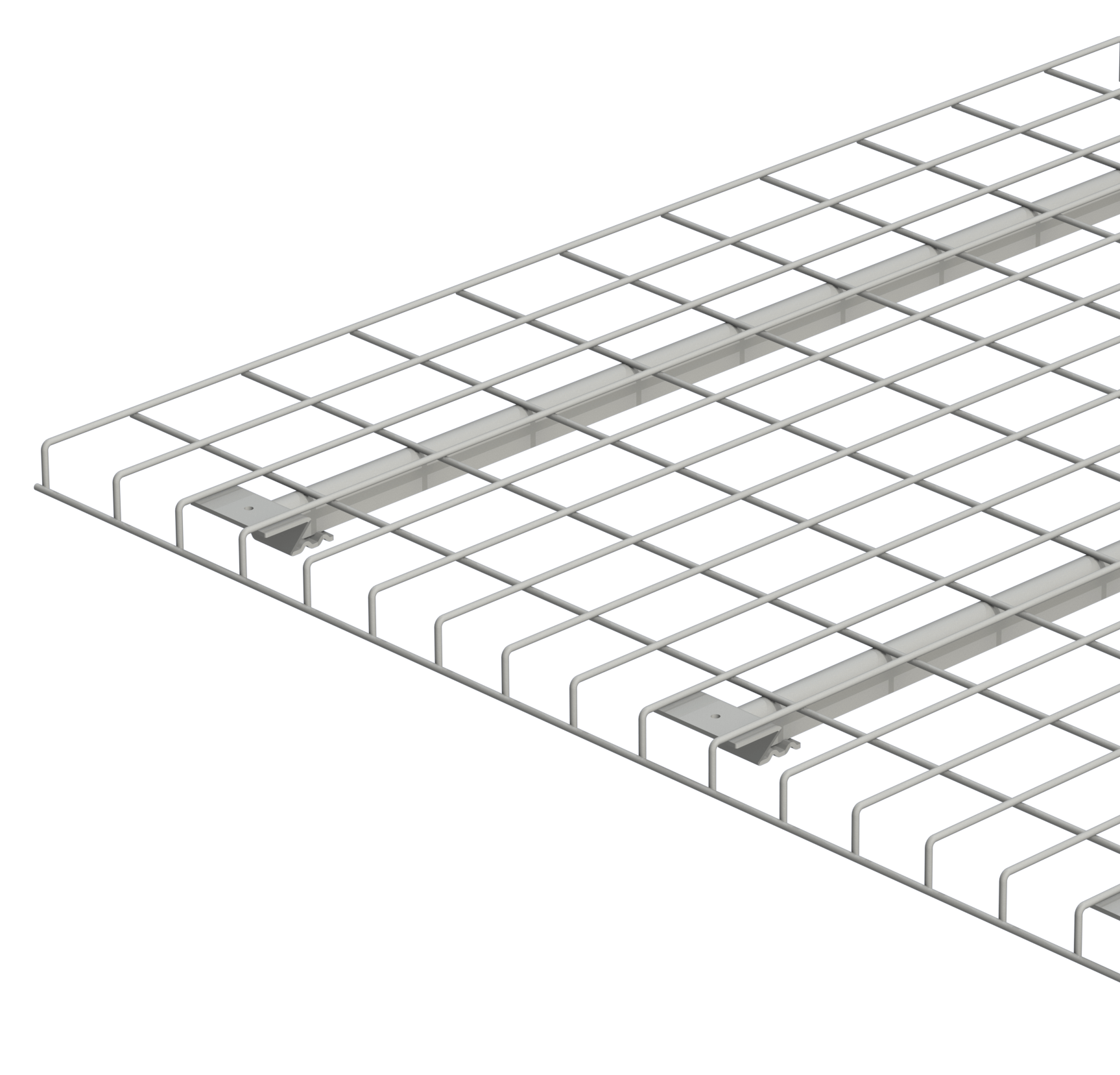

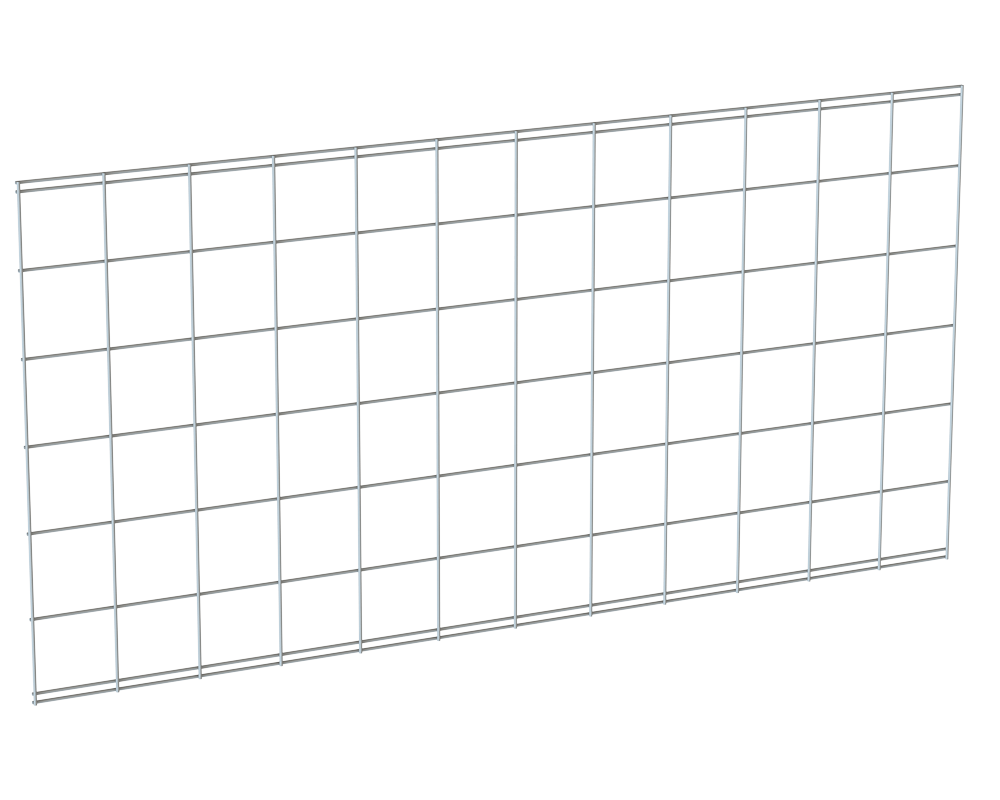

Wire Mesh Decking

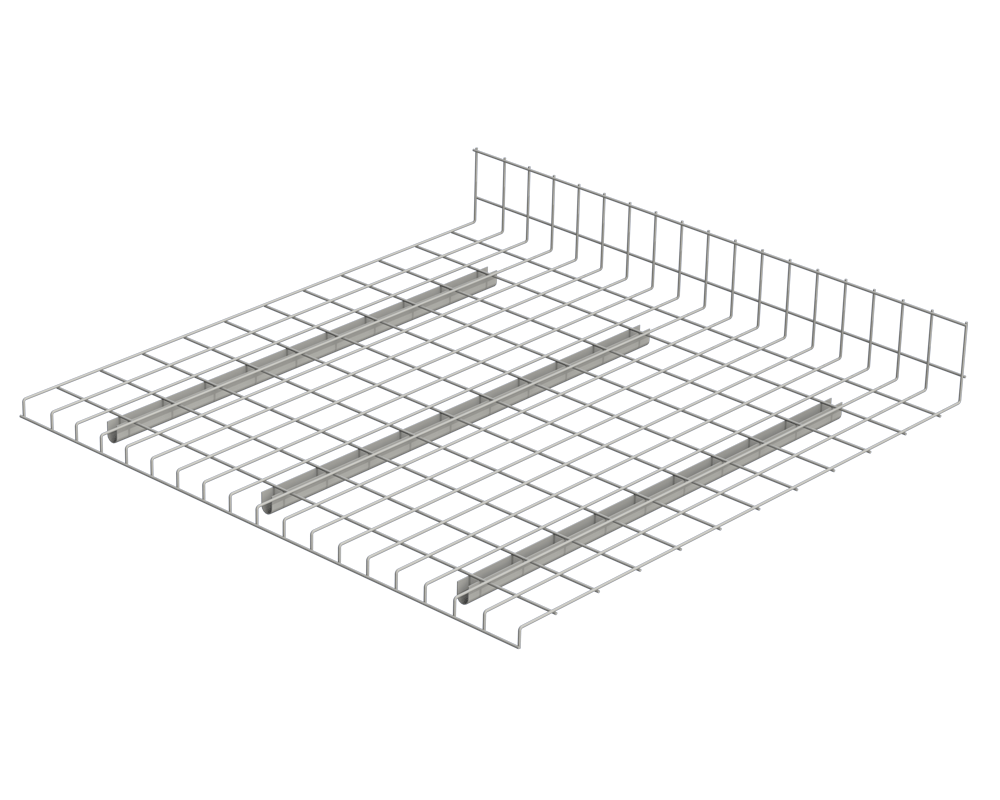

ITC engineers and manufactures wire mesh decking specific to your customers’ needs based on capacity and application. This includes light duty wire mesh for lower capacities and heavy duty mesh for heavier or non-uniform loads. We also offer outdoor decks that are zinc-plated or hot-dip galvanized for exceptional weather resistance, as well as anchored decks that can be secured to the beam to stop beam separation and prevent deck movement.

ITC’s high-tech automated machines weld the wire with accuracy and consistency into flat mesh panels. These panels are then mechanically formed and transported for additional welding of support channels. The powder coat is applied electrostatically before the product travels through a sophisticated infrared convection oven to complete the curing process. Throughout the process, our quality control and testing team ensures that the product meets our exacting standards—and yours—before being shipped out.

ITC Wire Mesh Decking Advantages

Ease of Use

Simple installation

Simple installation High visibility for inventory inspection

High visibility for inventory inspection Minimizes dirt build-up

Minimizes dirt build-up Improves air circulation

Improves air circulation

Financial Savings

Increases capacity

Decreases insurance premiums

Eliminates the expense of installing multilevel sprinklers

Eliminates the expense of installing multilevel sprinklers

Improved Safety

Promotes Safety by Limiting Product Fall-Through

Promotes Safety by Limiting Product Fall-Through Increases overhead sprinkler effectiveness

Increases overhead sprinkler effectiveness Open mesh provides quicker detection

Open mesh provides quicker detection Limits product fall-through

Limits product fall-through Promotes Safety by Limiting Product Fall-Through

Promotes Safety by Limiting Product Fall-Through

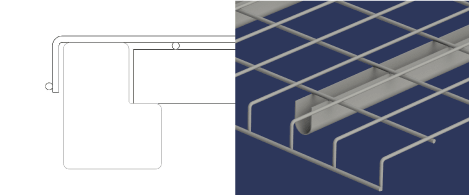

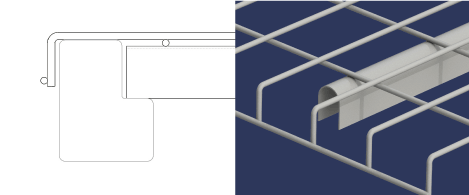

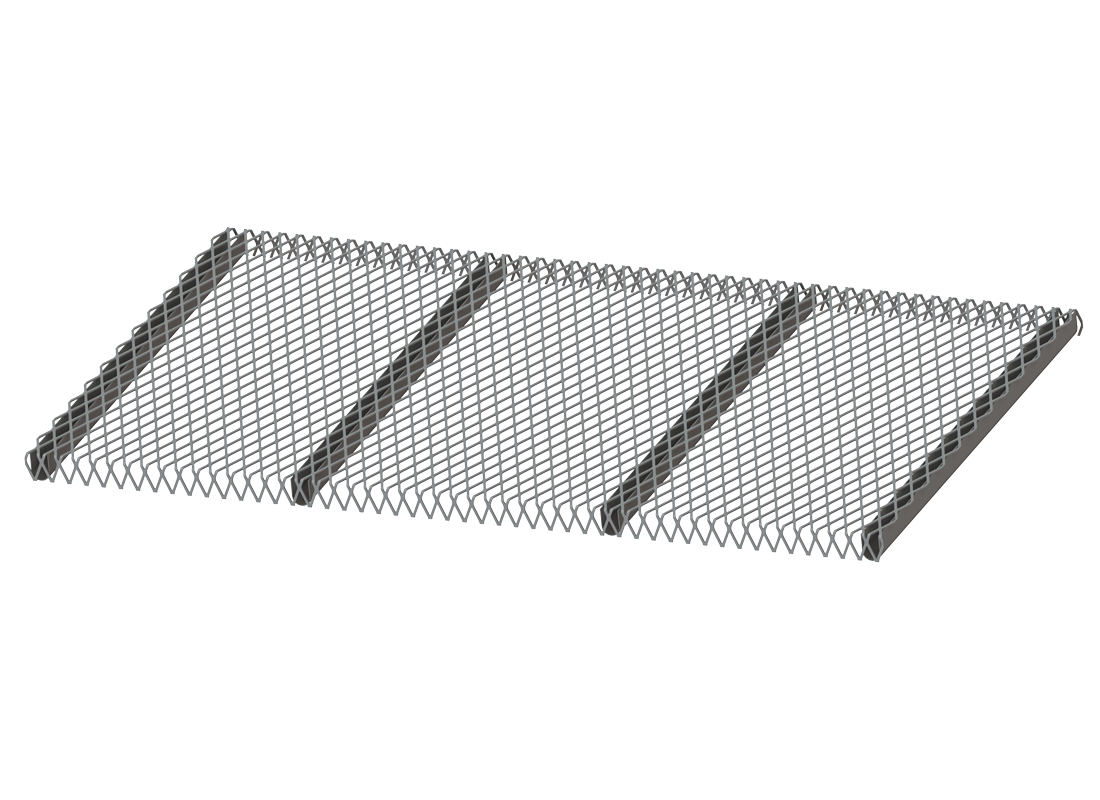

Standard / Step

Structural Deck

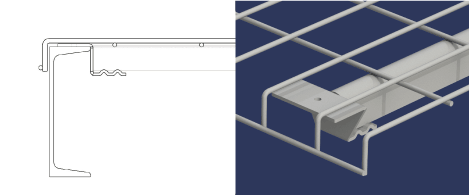

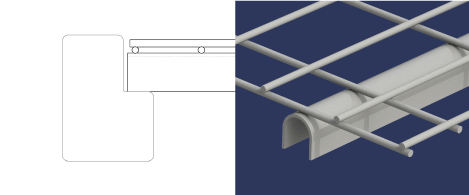

Flared Channel

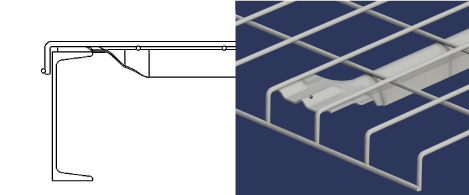

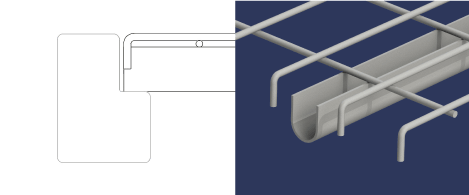

Inverted

Flat Flush

Flush Waterfall

Grid Patterns

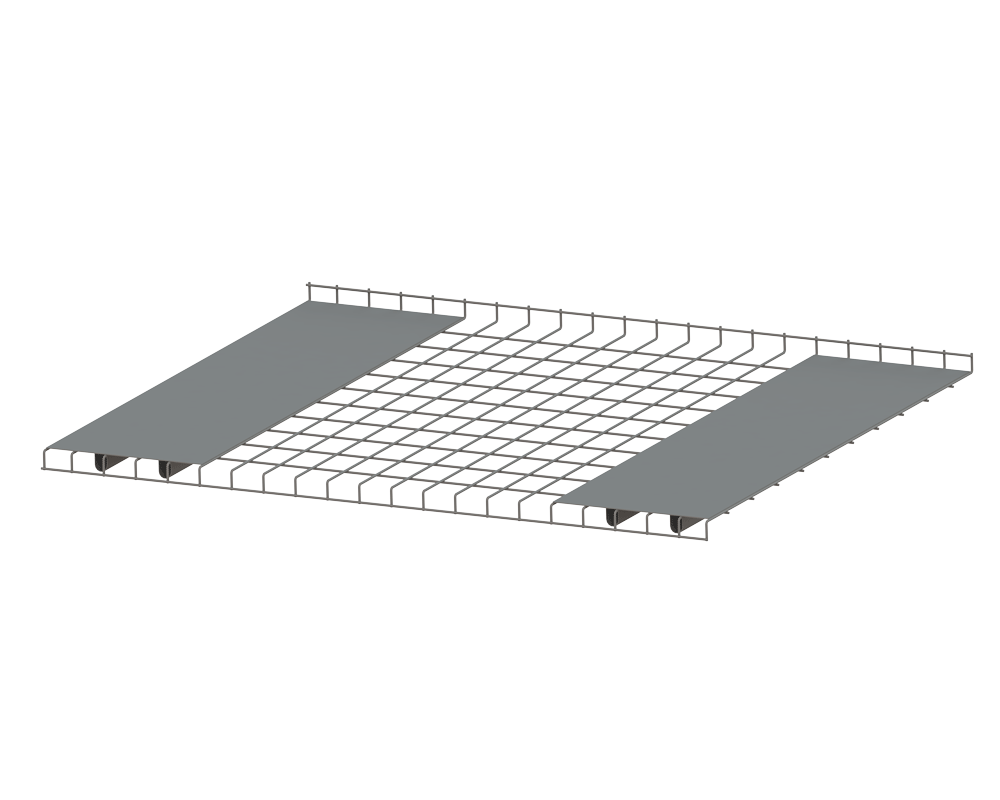

The standard grid pattern for our wire mesh decking is 2.5" x 4", but ITC also offers tighter grid patterns for customers who need to shelve smaller objects. For hand-stack applications, for example, a 1" x 4" or 1" x 6" grid pattern features top wires that are only an inch apart to handle even the smallest boxes. ITC’s smallest grid capability is 1" x 2".Flush Decks

Flush decks, commonly used on lower levels for hand stacking and order-picking applications, can be fabricated with an inside waterfall or a flat flush edge, where the end wire comes to the inside edge of the beam.Support Channel / Capacity

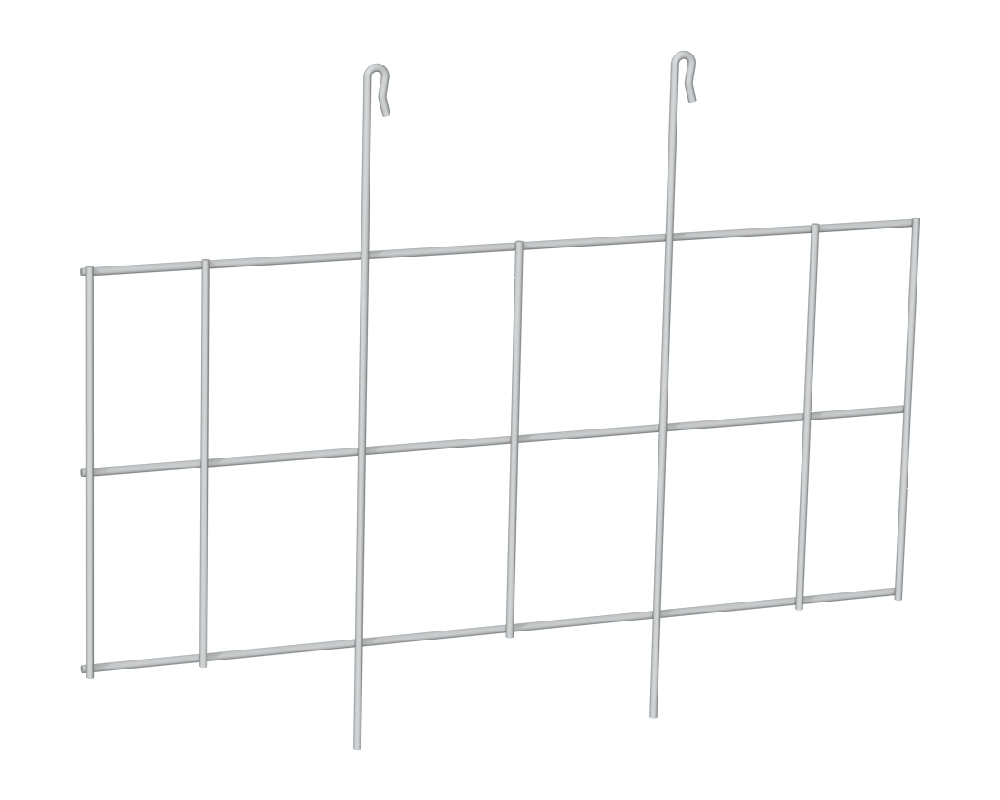

Steel support channels welded to the bottom of pallet rack decks supply the load-bearing capacity. Most decks use three support channels to achieve the standard 2,500 lbs. capacity rating. Step channels provide greater strength than flared channels. For some applications, such as food storage, inverted channels are used.Waterfalls

Although the standard for decking is the 1½" outside waterfall, variations are available for custom applications. Waterfalls may be upturned to create a backstop and prevent the hand-stacked product from interfering with the flue space.Stock Sizes

Size

24 x 46 • 3

36 x 46 • 3

42 x 46 • 3

42 x 46 • 3

42 x 52 • 3

42 x 58 • 3

44 x 46 • 3

48 x 46 • 3

48 x 52 • 3

48 x 58 • 4

Part #

C-ITC01-3646-G

C-ITC01-4246-G

C-ITC02-4246-G

C-ITC01-4252-G

C-ITC01-4258-G

C-ITC01-4446-G

C-ITC01-4846-G

C-ITC01-4852-G

C-ITC01-4858-G